Press Stand Water Reclaim System

Kanata, Ontario

AstenJohnson Kanata Business Support Center installed a press stand water reclaim system in September 2024.

This system recirculates water between the reservoir and the vacuum pump in the press stand machine. The water is used to seal and cool the Uhle box. The new system recycles the used water by reclaiming it and recirculating it. The water is saved from entering the city sewer as waste.

The reclamation system is saving approximately 3850 m³ water, while the cost savings are around $15,000 annually.

The operators were trained, and the project is running.

Exchanging Books for Vegetables

Suzhou, China

On November 28th and December 6th 2024, AstenJohnson Suzhou organized “Exchanging books for vegetables.”

More than one hundred associates exchanged books for seasonal fresh vegetables by donating unused books, and brought greens and health home. The company will sort out the collected books and donate them to relevant social welfare organizations.

In this way, the company promotes recycling of resources, and passes on knowledge and love, realizing the dual benefits of environmental protection and practicality. Rex Hao said when donating the books, “I am very grateful to the company for providing us such a public welfare platform, and being able to exchange the books for fresh vegetables. It lets the unused books reflect their value again, and the fresh vegetables also bring health to my family.”

EcoFi

Hampton, NH

AJ Nonwovens Hampton has long been using recycled materials. They use up to 100% recycled materials in a variety of markets, including automotive, filtration, roofing, flooring, composites, boats, and many others.

Within its range of recycled raw material, AJ Nonwovens Hampton developed Eco-fi.

Eco-fi is a PET fiber made with 100% recycled plastic bottles. It can be used to make many textile product such as clothing, auto interiors, and craft felts. It can be blended with other fibers, such as cotton or wool, for enhanced qualities.

Our supply of recycled PET is received with product certification and specification test data.

Shredder

Eupen, Belgium

AstenJohnson Eupen installed and commissioned a brand-new shredder in April 2024.

The machine performs well by shredding Eupen waste clothing material into very small pieces. Cutting production waste in small pieces is an essential condition for recycling. AJ Eupen is actually in contact with several potential partners.

This represents a big step toward better recycling.

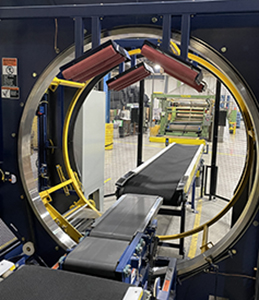

Roll Stretch Wrappers

Hampton, New Hampshire

Reducing waste going to landfills start by producing less waste in every step of the production, including packaging.

In late 2023, AstenJohnson Nonwovens Hampton installed two roll stretch wrappers.

The reduction in plastic used for the packaging is around 200 to 300% in density. This machine also allows for CO2 emissions reduction.

As a graphic designer, I try to show that design and sustainability can coexist in harmony. I prefer sustainable options for our merchandising, showcase our sustainable efforts through social media, and practice sustainable behavior in the office. I believe every action matters.

It's a challenge I take up with passion every day. I firmly believe that we can also contribute to a better future through our professional actions.

Gene Simon Corporate Visual Identity manager, Eupen

Shredder & Pelletizer

Hampton, New Hampshire

AJ Nonwovens Hampton is proud to announce the successful installation and implementation of its new recycling equipment in 2023. The pelletizer and shredder represent a huge step forward in the sustainable future of the company.

The new machines will allow AJ Nonwovens Hampton to recycle all its PET waste directly on site. After being thoroughly separated from other materials, PET waste is first cut into very small pieces through the shredder. The shredded material is then lead through conveyor belts to the pelletizer. Once created, those pellets are raw material for Hampton to use in their Fiber lines. The Fiber created is then used in the Fabric lines to create the final product for customers.

AJ Nonwovens Hampton is not the only site that will benefit from this equipment. Thanks to its capacity, PET waste from several North American AJ PMC sites will be collected and recycled too. About 4 million pounds will be saved inside the company.

Success Story

Eupen, Belgium

The Eupen sales team arranged a pickup of about 90 steel tubes with a local customer. This represents another step in developing our sustainable efforts and prioritize reuse when possible.

Bottle Flake — AJ Nonwovens

HAMPTON, NEW HAMPSHIRE

As a manufacturer of PET fiber, a larger portion of the PET resin used by AJ Nonwovens Hampton to make the fiber comes from recycled materials, including beverage bottles. Since 2020, 80% of AJ Nonwovens Hampton PET Resin was recycled material, including post-consumer and post-industrial recycled material. While postindustrial sources include bottle making scrap, sheet and film operations, post-consumer flakes and pellets are coming from recycled bottles.

AJ Nonwovens Hampton used about 2.6 million bottles since 2020 which otherwise might have gone into a landfill.

Learn More About the Process

Success Story

Eupen, Belgium

Late 2023, AstenJohnson Eupen enhanced their efforts in waste recycling, focusing on the proper collection of PMD waste (Plastic packaging, Metal packaging, Drinks cartons).

Since the implementation of the new rules, the proportion of waste correctly separated and recycled significantly increased in just a few months.

We are proud to see the associates’ response to better waste collection!

Pelletizing the Plastic

Suzhou, China

In an effort to build a circular economy, a key sustainability value, we collaborate with partners to create circular opportunities. An example is our waste scrap recycling in our Asian sites. We work with a local partner that takes our scrap waste and gives it new life by turning it into new items.

How does this work?

The Process:

Side trim from weaving and residual weaving monofilament is delivered to the chipping station at the recycling partner.

The recycling partner feeds the pelletizer and produces the chips. The chips are loaded into super sacks.

End use is for garbage cans, buckets, storage bins, and other non-food applications.

Success Story

Valleyfield, Quebec

While some customers are reusing fabric for gardening to prevent weeds, others are using press felt for carpet at their campground site. The "Wooden box garden" is another nice example. In Valleyfield, the packaging boxes were reused by a customer to create a garden. AstenJohnson associates also reuse the boxes for projects at home.

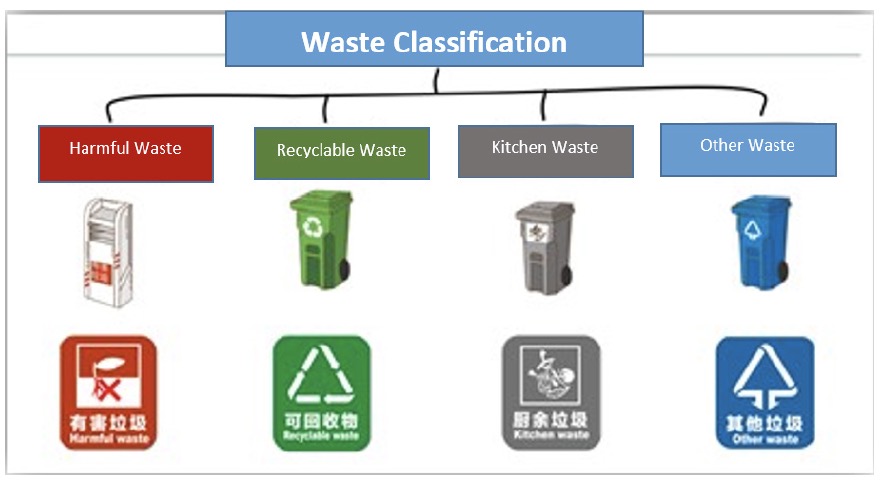

Green Belt Project

Suzhou, China

The LEAN Sigma program is an excellent complement to Sustainability Goals. Associates working toward Green Belt status develop projects focused on continual improvements that will remove waste and inefficiencies, and improve working conditions. In addition, these projects address issues that are important to AstenJohnson.

One of the projects we’ve developed is the garbage classification project. Garbage is identified as 4 main categories:

- Food waste

- Recyclable waste

- Harmful waste

- Others

I am actively engaged in the garbage classification project, because environment protection is obviously benefitting ourselves, our children and our next generations. Practicing 'NO WASTE' in work and life, and influencing my associates as much as possible are important matters. The more we save, the more we contribute to those who are potentially in need.

Helen Zhao HR Manager, Suzhou

Electronics Recycling

Charleston, SC

Associates at AstenJohnson Charleston participated in electronics recycling drives in 2022 and 2023. In 2024, they made it a quarterly event. In 2025, the Charleston site had a larger event tied into an office cleaning action and recycled many of the outdated electronics that had been filed away.

Eupen, Belgium

In 2024, AstenJohnson Eupen recycled 10 devices. While 7 phones were used for spare parts, 3 were put back in circulation. Thanks to this donation, one device will be given to a Belgian local organization.

In 2021, AstenJohnson Eupen recycled 14 smartphones in collaboration with a recycling partner. 6 devices were put back into circulation in Europe and 8 others were used for spare parts to recycle and repair other phones. In addition to the direct reuse of the smartphones, this collect generated some money that contributed to donate reconditioned appliances to BXL refugees.

Writing Tools Recycling

Strakonice, Czech Republic

Eupen, Belgium

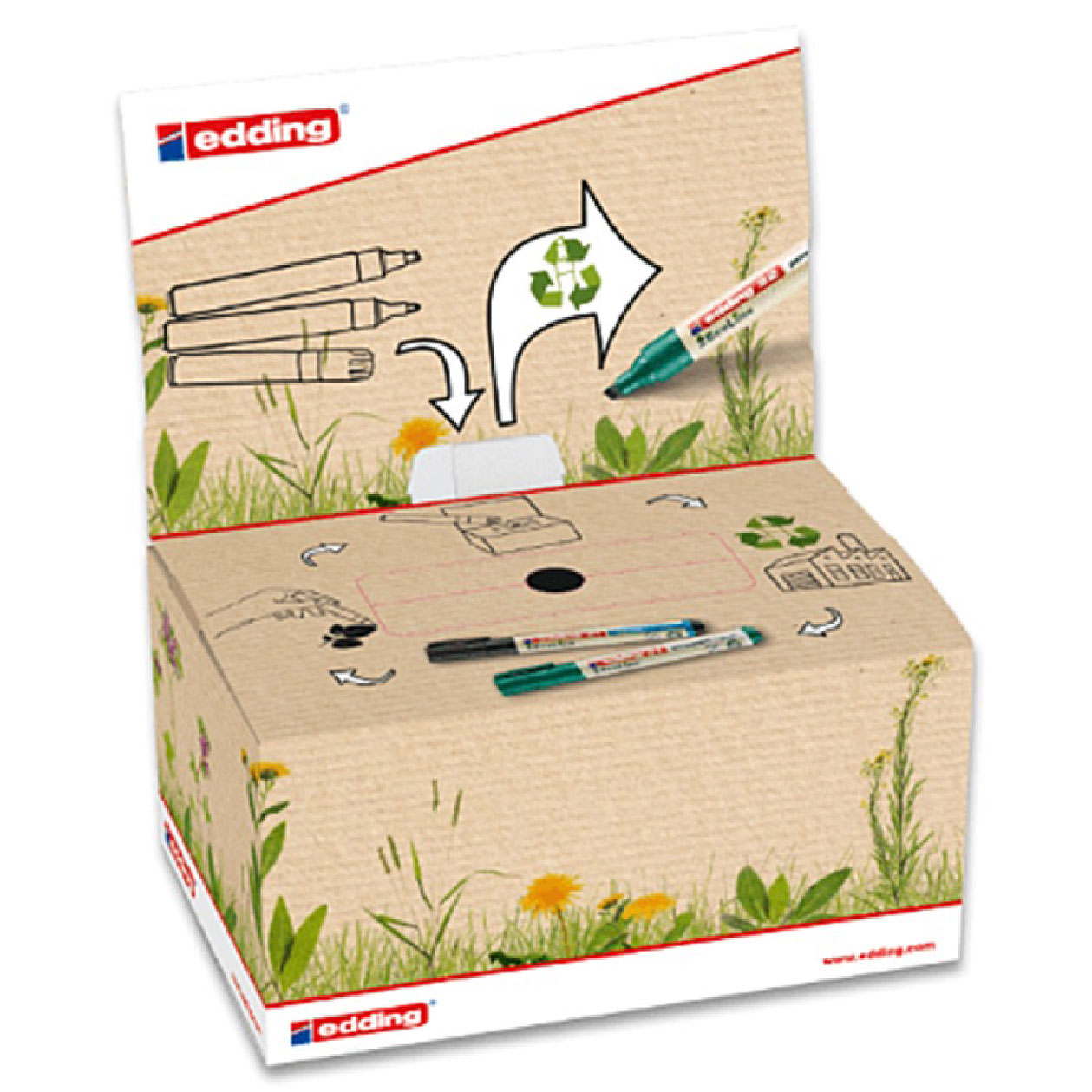

AstenJohnson Strakonice and AstenJohnson Eupen implemented a system to recycle empty, written-out markers, highlighters, pens, rollerball pens and pencils. They are collected in recycling boxes located at several locations in our plant. The capacity of the box is 170 markers, but pens and narrower markers can hold up to 300.

The plastic parts obtained by dismantling the discarded pens are then shredded and the resulting material is used in the production of new markers.

Eupen, Belgium

AstenJohnson Strakonice and AstenJohnson Eupen implemented a system to recycle empty, written-out markers, highlighters, pens, rollerball pens and pencils. They are collected in recycling boxes located at several locations in our plant. The capacity of the box is 170 markers, but pens and narrower markers can hold up to 300.

The plastic parts obtained by dismantling the discarded pens are then shredded and the resulting material is used in the production of new markers.